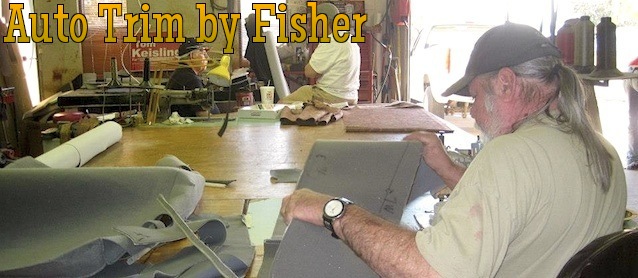

What follows is a touching personal account by Marc Fisher of Auto Trim by Fisher in Lubbock, TX on how he got his start in auto upholstery, as well as a few of the lessons he learned along the way about how to compensate employees.

These are the types of stories and life lessons that only true veterans of the craft could share…

“Fixin’ to get rich”

I’ve been working in the auto trim industry since the day I was born. In fact, I’m a third generation trimmer. My grandmother, Muno, went in business in 1948 in the back of a gas station. My dad took the seats out of the cars and Muno cut and sewed them up. At the time, my granddad, Daddy Bill, worked at an auto-service place installing auto glass. He cut the glass and installed it. It was all laminated flat glass back then. In 1950, Daddy Bill and Muno moved into a building and Started B&M Trim & Glass. My Uncle Billy, who worked for PPG Glass Co at the time, quit and joined them too.

I cut my teeth in that shop. Daddy Bill would buy us a Coke from the soda machine for sweeping the floor or cleaning out a drawer. There was a peanut machine next to the soda machine. We’d get a nickel’s worth of peanuts and put them in our Cokes. I was 8 yrs old when Muno would send me to the corner drug store for 10 single-edge razor blades at least once a day. That was smack in the middle of downtown Lubbock, TX in 1964.

The first real job I ever had was ripping out seat covers for Muno. I marked them and cut the thread with a razor blade. I learned exactly how to unravel chain stitches. I’d get a dollar or maybe 5-yee haw!!!

When I was in junior high, my dad said, “Marc, I’m going to let you do all the motorcycle seats I take in, give you the material and let you keep the money.” I went by every motorcycle shop in town and recovered all there seats, and the first week I made $200. I went back the second week and they all said, “No, you got us all fixed up last week.”

Dammitt! I thought I was fixin’ to get rich, but hell no. I recovered every seat in town in a week!

The joys of salary

When I was 16, I was working full time for $75 per week. I was the carpet man. I installed all the carpet. By the time I was 20, I could do just about anything in the shop. I was making $125 per week then. My brother Dave was making $175. Because we were on salary, we could mess around. Every day we would take a coffee break at 9 am and go eat breakfast. We would be gone for an hour usually. Then lunch at 12 pm for an hour, and another break at 3 pm for 30 minutes to an hour.

We had friends who were mechanics making $400 per week. I love my family and all, but a man has to make a decent living. My brother and I left in 1976 to open up our own shop. I was 20 and he was 22. Over the years, we worked in range of scenarios: Partners, I worked for him and at one point he worked for me. We parted ways decades ago.

Over the years, I’ve experimented with a number of ways to compensate my employees.

Out of Commission

We got paid salary when we worked for Muno. I knew how I took advantage of that and decided not to let my employees have the luxury. So I went out and got a time clock. If you don’t work, you don’t get paid.

I had some employees that it seemed were always walking around looking up at the ceiling. To inspire them to work harder, I decided to put them on commission.

I looked for a flat-rate book of on auto upholstery. I found one, but it didn’t have much at all. So I set out to create one just like mechanics and body shops have. They all charge the same amount of time per job. Their hourly rates may differ, but the times are always the same.

I created my flat-rate book in QuickBooks. I piled up months of invoices for jobs we did. I read through the invoices and decided how much time it should take to complete each job. My item list has 200 or so items with specific times tables.

I discussed these times with Luis, who has been with me since 1976. We talked about how long we thought it should take to do a padded headliner, for example. We broke that down into car, pick up truck (regular cab, xt cab, crew cab), SUV, etc. We then estimated times for sun visors, ws posts, sunroof sunshades, etc – as all of these add to the price of a headliner.

Now, I have just about every job we do broken down into specific elements and labor times assigned to each one. It took me several months to complete, but it was worth it.

It seemed like a foolproof idea at the time: I’d put all my employees on commission where they could make more money if they worked harder, and I didn’t have to worry about them goofing around any more. I got mixed reactions though.

After a few weeks of this, I noticed we were having way too many customers comeback with complaints. I attempted several different ways to fix this: If someone had a comeback, he had to fix it. I even tried fining them for making mistakes.

However, instead of getting better, it got worse.

No one wanted to clean up. No one wanted to go on delivery. They would get upset if someone else got a job that paid better than theirs. The quality of our work went down considerably. Employees were stealing jobs from each other. They would argue about their paychecks. It was a nightmare!

Hourly pay + incentives

I eventually decided to scrap the commission model and go back to hourly pay, plus incentives for good work. I also give raises when an installer learns more and gets better and faster at his job.

I weeded out the slackers and only kept the hardest workers. I also started paying top wages compared to other shops in town, and provided insurance.

I’ve had one employee, Luis, since 1976. Another, Richard, since 1978. My son, my dad, son-in-law and stepson all work for me. What’s more, Luis’ nephew and son-in-law are also on the team. My wife and son’s girlfriend are in the office. We also have a few others working. In total, our team is 14 strong.

Everyone seems to enjoy their job, and we all get along like one big happy family.

Read other great articles by Marc Fisher on The Hog Ring by clicking here.

We still use the flat rate book to price jobs. It’s all on the computer. Every year I go up 10% on the prices in the computer across the board. The times stay the same, but the hourly rate changes. We’re up to about $87 per hour.

Absolutely love this story, Marc. There are a lot of valuable insights and lessons here. Thanks for sharing!

Um, peanuts in Coke? Is that a regional thing, like boiled peanuts?

That out of the way, hourly plus incentive is the best payment system I know of. You can plan, and when you excel you get rewarded. Everyone wins!

Salted peanuts from a penny machine. A coke cost a dime, and the bottle was worth 2-3 cents.

What a great article! Thanks for sharing this with us Mark. You brought up some aspects of the commission model that I never considered. For example no one wanting to clean up, go on delivery, arguments between employees about stealing higher paying jobs, and quality of work suffering. All of those problems make sense, I just never considered them because I’ve had no personal experience with paying employees by commission.

Thanks again Mark. This article was very insightful.

That is an awesome story, thank you for sharing it. My father used to put peanuts in our coke when we were kids and we really enjoyed it!!

Marc, have you ever considered making your flat rate book available to other trimmers, even at a cost? If not, would you consider it…I’d be interested in investing in a tool like that. I’ve tried to do that myself and am surprised there is no standard for upholstery/trimmers.