Giving fair price estimates is one of the most important skills that an independent auto trimmer needs in order to succeed. While over charging isn’t good for customers, under charging isn’t good for shops. In effect, estimates can either make or break an auto upholstery business.

Knowing what is needed to complete a project is important. Accurately measuring for materials is a valuable skill, as is being able to convert raw dimensions into yardage and board feet. Underestimating leads to additional costs for you and the customer, and we all know what happens when you hand a final bill to a customer that’s more than what he was expecting to pay.

To avoid the embarrassment of under estimating a project, you should know what it requires for materials and time.

Start by breaking down the project into elements: seats, door panels, headliner, carpet, etc. Address each one separately. Your basic bucket seat, for example, requires about three yards of cover material. There are also support materials the customer never considers – including foam buns, sew foam, cotton batting, burlap, welt cord, thread and of course… hog rings.

Other supplies that are required to finish the seat are rubber bumpers, trim screws, buttons and maybe spray dye for the plastic parts. Once you’ve compiled a list of what’s needed, consider other issues that might arise. For instance, bolster springs are usually broken and need to be replaced, a cracked frame needs to be welded and seat tracks also need to be reconditioned.

Next, take your materials list and assign each item a price – not the price you paid, but the retail or resale price of the item being sold to the customer plus shipping costs. This is your profit margin. It’s how you make a living, so don’t give away the store.

Now factor in your labor charge for the time it takes you to complete the project. Some shops charge by the hour, others by the piece. Whatever works for you is the correct way to charge. How you determine your labor rate is based on the economy in your area and what customers are willing to pay.

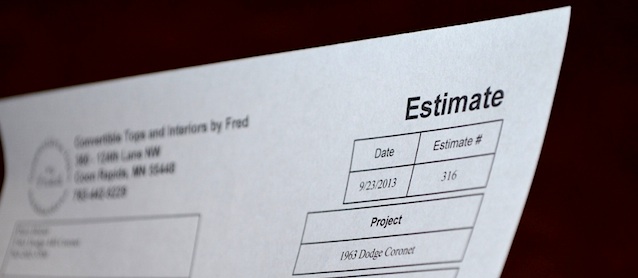

Repeat the process for each element a customer asks you to trim. Add everything up and you have your estimate.

Before handing it to a customer, take the time to review your estimate to ensure you didn’t forget anything. It’s good to be as precise as possible.

Try not to give “ballpark” estimates, as they tend to stick in the minds of customers. If you do give one, make it high. This way when your final bill arrives, it will be lower than what your customer expected and he’ll be happier.

Developing a reputation for delivering projects over budget will cost you future jobs. It tells customers that you don’t know what you’re doing, and may even put you in the position where you feel obliged to eat your losses. That can be detrimental to the survival of your business.

All in all, when it comes to estimates, experience is the best teacher.

Fred Mattson is owner and operator of Convertible Tops & Interiors by Fred in Coon Rapids, MN. He specializes in Corvettes and scratch-built restorations on vintage cars. To read more articles by Fred, click here.

Good stuff Fred!! Great article!

Good information here, Fred. Estimating can be a really hard thing for beginners – especially charging enough to make a profit. You mentioned estimating on the high side, which is what I always do when I have doubts about the length of time a project will take. It seems like half the time, I wind up putting in as much time as the high end estimate (so I actually get paid for my work), and half the time I come out under the estimate. The customer is very happy when I come out under. They are not so happy if I come out over.

Beginners worry that they are going to lose the job if they charge too much. Look at it this way: the work needs to be done. Be confident and explain what needs to be done and what the estimate includes, just like Fred describes in this article. Tell them that there is a right way to do it and a wrong way to do it, and anything less than what you are explaining is less than what is needed to make it right. I try to keep a disassembled seat around so I can show people that underneath the cover there is a frame, which can get bent or broken, springs that can break, cushioning that deteriorates and finally the cover. Cheap materials and sloppy work will cause it all to wear out much faster.

If the customer wants a job that is done right, they will feel confident in your knowledge and ability. If all they want is cheap, then let them take their chances with people that do cheap work. Doing cheap and sloppy work yourself will only tarnish your reputation. I’ve seen people come back sheepishly and pay me to do it right.

Sticking to doing the job right will give you a reputation that may take a little while to establish, but once people realize that you do the best job that can be done, they won’t go anywhere else. Think about the kind of mechanic you want to take your car to.

Fred – you are a true master trimmer who wants our trade to have a good reputation. Thank you.

–Jim

This is great information! I am relatively new still at estimating on my own and it is pretty intimidating. Thank you Fred for the initial article and thank you Jim for your informative comment! I have been trying to do what was said already so it reinforces that I’m headed down the right path.

Fred makes a great point about ballpark estimates. People remember what they want to remember, and if your ballpark is low, then that will be all that is remembered. Ballpark high, price low, and they will think you are a miracle worker!

Enjoyed this article. I’m new to the business, and this is one of the areas I find difficult. I usually end up under estimating the time it actually takes. Is there a guide as far as labor rates in certain areas of the country for me to reference? Im having a hard time with that, thinking I might be overcharging on the labor.

Thank you!