To back or not to back? That is the question. We want to know where you stand on reinforcing French seams.

When I was first taught how to sew many years ago, I was instructed to always back a French seam with listing tape to strengthen it. It’s a habit I still carry to this day, yet as the years go by I notice that less OEMs are doing so and I’m wondering why.

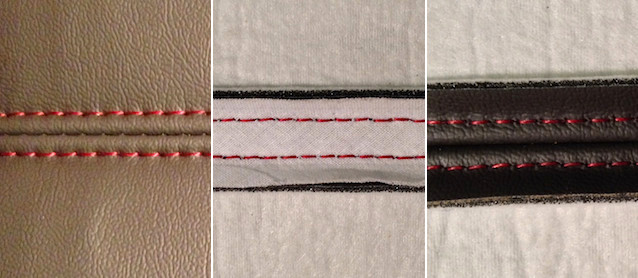

Everyone knows the basics of a proper French seam. After sewing two pieces together, you fold half of your seam allowance to the left, half to the right and sew a line of stitches over each equidistantly from the center seam. Simple as a dimple ain’t it?

The only question is: Should you back French seams with listing tape or some other cloth to strengthen them? Whereas proper instruction says “yes,” automakers are increasingly saying “no.”

I first noticed it when airbags became commonplace in car seats, and figured it made sense to make their stitches purposely weaker so that the bags could burst through seat covers. But that only explains the driver and passenger backrests. Why then are entire seat bottoms and rear seats being sewn without any reinforcement on their French seams?

What do you think? Do you reinforce your French seams? Is it even necessary? If so, why are automakers failing to do it? Let us know your thoughts in the comments section below.

It would only be necessary when you’re wanting a stronger seam. Otherwise a French seam without the backing is just there for decoration. It just becomes a regular seam that looks nicer.

It is a good thing to back the seams in heavy contact areas where you slide in and out of the vehicle. Otherwise I never backed them.

This is not strictly a french seam, it is a open seam with top decrotive stitching.

A French seam has no raw edges showing and Is a better way to finish a edge on finer fabrics

Barbara

Upholterer

Fashion garment, and Costumier Teacher

Thank you for the clarification. As I read the OP’s article I began to think maybe I was confused.

MOST OF ALL, NOT A REAL FRENCH SEAM WITHOUT REINFORCMENT! I WAS TRAINED THAT WAY ! BUT MANY ROOKIES DO NOT DO IT! JUST NOT THE RIGHT WAY, ALWAYS PUT MUSLIN OR A GOOD BACKING ON A TRUE FRENCH SEAM! JUST THE REAL DEAL! NO CHEATING ON QUALITY CRAFTSMANSHIP, ONLY THE ARTISAN KNOWS!

Always back on seats, not necessary on seams that don’t get any wear and tear.

Retired… It Would Seem the Coreect Way would Be To Back If, And I Say If You Want The Seams To Last. There Are A Lot Of People Who Think Just the Opisste Of Others And The Thoughts AreUsually Of The Bottom Line Only.. If It Were My Classic I Were Restoring I Would Want the Seams To Last . This Is Just My Opinion And I Doubt Its Worth 2 ó.

Even if you back the stitch on say a bolster it’s quite rare the sew together stitch will break unless the panel is worn through wearing through the sew stitch, even with the backing your still have a spit seam and the cover will need attention?

Maybe it’s there to cover any sew foam/ seat foam colour through the stitch?

I read somewhere that the French seam is the strongest seam we have in auto upholstery. The reason is the backing locks both sides of the material together more effectively than top stitching. I went on to discuss non backed seams for decoration only and where they should be used. Makes sense and seams they are both right. Did you catch what I did there?

We back all our french seams unless its near an airbag. Not only for strength but for longevity as well. After a many years of abuse a seam can bust however with the french seam backed less stretch is allowed and last a lot longer. Plus a proper backed and trimmed seam will flow smoother around corners with more evenness and consistency .

You’re the only one I’ve seen to reference the “lay” of the seam. I think that’s more important than strength. I use it in marine seats to add proper lay and additional water-resistance.

The seat just contours better with the backing. Speaking of which, do any of you have a good source for listing tape? I am in downstate NY and am having trouble finding a good vendor for 2 inch and above. Thanks very much!

Kristie, I am also looking for a vendor. We are located in Little Rock Arkansas. If you have found a vendor could you please share?

Thank you,

Kris Tidwell

As a rule of thumb I do it on high traffic areas. Anything that is a vanity pieces that will see no contact other than cleaning, I cheat. The only exceptions where I am torn(pun intended) is on center consoles where I turn out better looking storage lids without the backing, but am caused more warranty work if I don’t.

Over the years I have done them

Both ways in high wear areas. And I have not seen one wear or split faster than the other. If it fails it’s usually because the seat cover it self has torn from wear. Thread has come a long way in the last decade and I think that has a lot to do with this question. I can’t definitively say one way is better as I do still do both depending on the application. But I don’t think it’s as necessary as it once was.

I started in auto/boat upholstery and have been in aviation upholstery for the last 30 years. My first two years we backed French seams. I moved on to other completion centers where none of them backed seams. I have not found any evidence of any backing of seams when doing refurbished either.

An interesting topic to discussion. I think, it depends on the place where the ‘french seams’/’double stitches’ would go. I agree with the ‘backing reinforcement strip’ if they go on interior seats. Otherwise, it would be considered as a ‘simple closing sewing’ with double stitches as decorative. The ‘backing sewn strip’ would help to keep the seams ‘closed’ and not expose the ‘stitching threads’ directly to the sunrays adding more durability. This ‘backing reinforcement’ also adds some force to the seams to alleviate tensions while sitting on.

It’s only a particular point of view.

Been doing this for 45 years and I used to back the seam until I tried it once without the backing and never looked back. I have never had a comeback and frankly, they look better and less bulky. Bulk is an issue as most everything I do is in heavier leather – especially if one french seam runs into another. I think it’s totally unnecessary besides being a pain in the neck and my custom jobs use french seams almost exclusively. Thanks

Been doing motorbike seats for 8 years and I’ve always backed my french seams for 2 reasons: Waterproofing and durability. Bikes are left to the elements of sun and rain. Water can seep through the crack and into the foam giving the rider a wet bum, and foam gets damaged underneath through time when it is kept moist. In terms of splitting, I am not worried of the thread as I use thick nylons, but the material itself splits through hard wear or eventually tear over time. I use vinyl tape when I want the seam laid low, or I use vinyl leatherette for a more puckered up look.

Was giving a singer industrial 111W103 vintage and just checking everywhere for instructions and sewing guides. Even just those using vintage ones so key words brought up your site. Question a bit old but wanted to say Ive sewn regular clothing for 4 decades. I’m a wing it kind of sewist. Can make costumes from thrift clothing but took a bit of formal design classes. This is not really a French seam. They are completely enclosed by sewing wrong sides together then another seam enclosing it. Like inside of a tote bag or some couture dresses. No raw edges. Another way is flat fell like on sides of jeans. By adding the backing before stitch I can see its an imitation of the French seam converted to auto sewing. In retail clothing and areas such as totes in last few decades see the short cut way like this too. If not backed that seam is worse than doing nothing. It in fact creates more stress. The stitches holding the seam are stressed by the pulling of the sewn side seams making it completely immovable, non flexible. The only way to go under stress is the first seam will break. Then a bear to fix, in clothing world because you have to unpick the decorative stitching to fix the joining seam. If in auto industry I would say always back it if doing it this way. It’s the only way to say its doing the work of a French seam. Look up French seam for clothing manufacture.

Easy answer : the 69 thread will out last the Cheap Synthetic vinyl , life span is 3 years , no need to reinforce cheap materials they use

Very good point.

Hello all, is it completely necessary to put bias / diagonal back listing tape, or is it ok to do it with “normal” straight woven fabric

Thanks!

Your article is very detailed and impressive to me, and I hope that you will send me more articles of this caliber in the future.