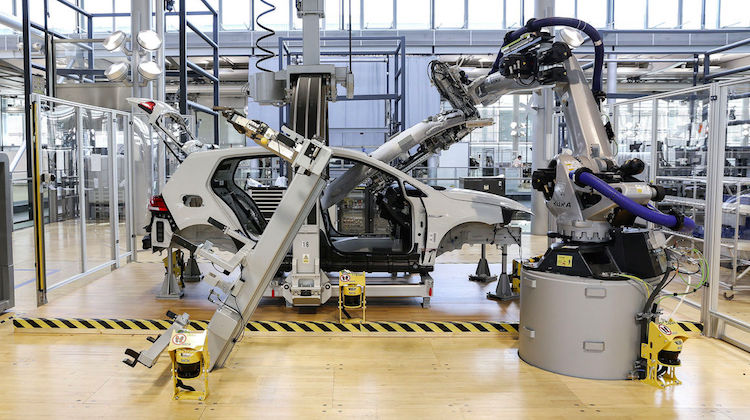

For the first time ever, an auto manufacturing plant is using robotics to install a headliner board in cars.

Volkswagen Group’s pilot factory in Dresden, Germany, is experimenting with the new technology, which involves the use of a giant robotic arm. This arm picks up an already trimmed headliner board and slides it into a vehicle cabin through the front window. It then clips the board in place.

Volkswagen is currently using the technology to install headliner boards in the e-Golf. However, it plans to expand its use to production of the all-electric ID.

“We want to achieve a 30% improvement in productivity in the Volkswagen brand factories by 2025 compared to 2018 to ensure our competitiveness in the long term and to make a decisive contribution to improving the profitability of the Volkswagen brand,” said Andreas Tostmann of Volkswagen Group. “To achieve this, the factories must become faster, leaner and more efficient.”

In a press release, Volkswagen says the overall goal is “to achieve automation of complex work steps within assembly.”

Of course, this isn’t good news for factory workers, who are likely to see job opportunities decrease as automation increases. But it is fascinating to watch the robotic arm in action.

It looks like the clips aren’t going to come out with out a fight.

What happens when the headliner needs to be recovered can the robot do that?

YANG GANG

Real easy when the front window is out of the car..And lets see it recover one..