One of the most heated debates in the auto upholstery industry is whether or not shops should repair seats equipped with side impact airbags (SIAB).

I see all kinds of attempts to explain the mysteries of how the seams are sewn, how to replicate them, and whether or not to attempt them at all. As someone who designs OEM seats and has worked for and with Tier 1 suppliers, hopefully I can shed light on the topic.

What constitutes a properly working airbag?

Just because an airbag inflates and blows a seam open doesn’t mean it works properly. Sure, it’s great the airbag does that but, as with most things, timing is everything.

The most dangerous comments I hear from trimmers who give airbag advice is “don’t worry, nothing can hold back that explosion” or “I’ve tested it myself on scrap seats and the seam blows open, no problem.” They mislead others into thinking that just because an airbag inflates, it will work as designed.

The fact is, airbag charges are designed to coincide with the movement of a human body within a crash condition. The charge is timed so that the airbag is fully inflated at the very instant before a body comes in contact with it. Too early, and the bag vents out leaving less cushion for an impact; too late, and the body is already in its path and gets slammed with the full force of the explosion.

To illustrate the point, watch this video of a watermelon dropping on an airbag as it inflates properly, and also with the bag inflating just seven hundredths of a second too late:

What can cause a bag to inflate at the incorrect time? Just about any item that goes into the construction of the airbag seam — which includes the machines used, thread, material and padding.

Manufacturers validate side impact airbags with an array of deployment tests whenever a condition exists that changes any aspect of how the seat is constructed. This is done even when changing manufacturing locations, despite using the EXACT same materials and thread for construction.

The tests vary by manufacturer, but typically consist of deploying airbags in very cold, very hot, and ambient temperatures to verify that the materials chosen perform equally well in all climates. Cold temperatures can cause some materials to crack or break, decreasing deployment times; hot temperatures can cause some materials to expand, therefore delaying deployment.

Failed tests are studied and changes to materials, stitching or other aspects are made to bring the seat into spec to ensure passenger safety.

The anatomy of side impact airbags

Not all airbags are designed the same, have the same parts, or are intended to deploy in the same manner. However, here’s how most typical airbags are constructed:

Aside from the actual airbag and its charge, there’s also an airbag chute, breakaway or functional seam, and chute reinforcement around surrounding areas.

The airbag chute is what directs that actual bag out of the seam and towards the passenger in a reliable manner. The ends of the chute are typically sewn into the seam by first tack-sewing the edges and then completing a join sew. Airbag chute material can vary, but is typically a woven nylon material with silicone coating on one side, which extends the life of the material and prevents burn-through during charge explosion.

Aside from the airbag itself, the chute takes the brunt of the charge force and makes a clear path for the bag to deploy. Although strong, tearing can happen if the material is over perforated by way of resewing the chute. This is one of the many reasons why you see warning labels on airbag seams instructing you to not resew.

It’s not some conspiracy from corporate America to keep you from getting work or fixing things yourself. A weakened chute could alter the path of the airbag deployment to an area that is not beneficial. Worst case scenario, it could even allow the bag to deploy within the seat, squeezing the occupant between the seat and the seat belt, while blowing seat particles throughout the cabin.

Breakaway and functional seams

Despite having one of the most important functions, the largest amount of misinformation floating around our industry is about breakaway seams. Guesswork, theories, and “what should work” are all over the internet misguiding trimmers and always pop up when questions about airbags are asked.

The specs of a breakaway seam are not hard to find if you spend a few minutes searching online.

Typically, these seams are sewn using nylon thread in a TEX size 30-90. They’re sewn at a stitch length that allows the seam to break at the desired speed (usually between 5-7 stitches per inch). Sometimes the bobbin thread is smaller than the top thread, and sometimes both are equal.

When it comes to sewing breakaway seams, there is no standard. Manufacturers set their own guidelines based on how they need the seam to perform. Trimmers often assume that as long as the thread is small or weak and the seat sews tight, that’s all that’s needed for the breakaway seam to perform as intended — but that’s incorrect.

While most trimmers are somewhat familiar with breakaway seams, some have never even heard of functional seams. These are adjacent or joining seams that must also tear open for proper deployment of an airbag. In many cases, these are just as critical as breakaway seams. In fact, they may even be sewn with the same specs.

The last piece of the breakaway or functional seams is typically the decorative top stitch, which can help reinforce the chute to the outer material. It’s important to note that seam selvage is always split open on an airbag seam so the two halves can separate cleanly. On a deck sew, only one side is flipped under with the other side floating, otherwise known as an “open deck.” On a French seam, both sides of the selvage are sewn under their respective side.

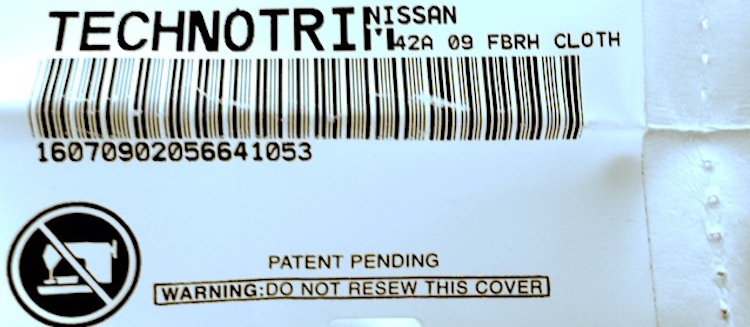

Airbag seam sewing machines are an instrument commonly used to ensure consistency and reliability of breakaway and functional seams. These machines track both tension and stitch count on critical areas of the airbag seam. Once complete, a barcode label is printed and sewn at the end of the seam, which allows that particular seam to be traced to a batch and lot number. Because an even seam break during an accident is crucial and defects can be deadly, these machines have become an industry standard to document a properly sewn airbag seam.

Chute reinforcement

In order to contain and direct the airbag itself, the back of the chute needs to be secured. Typically, this is done by joining the two halves of the chute together by way of a seam, although metal reinforcements and bonded attachment points are not uncommon.

It’s important to note that this joint is made to prevent any rearward or incorrect deployment of the airbag. It’s often sewn with heavy gauge thread (TEX 135-207), sometimes folding or double stitching to ensure no breakage upon deployment, as a failed reinforcement seam can be as detrimental as a poorly executed breakaway seam.

Sometimes, reinforcement efforts are done in areas around the breakaway seam as well to prevent flaps or parts of the trim cover from flying away and becoming projectiles.

Sensors and electronics

As more safety technology gets incorporated into cars, seats are also becoming smarter.

Manufacturers are increasingly using sensors to gather information on passengers to modify how an airbag can deploy more effectively. This may include everything from weight, height, and even how a passenger is seated.

Installing a new trim cover, even when the airbag is not part of the trim itself, can have drastic effect. By altering the layering of materials (trim and foam) on these sensors, you can easily alter the results of the sensors, causing confusion to the airbag system. In an accident, a full-grown adult might receive an airbag deployment program intended for someone much smaller or vice versa.

The amount of data collected in modern vehicles for safety purposes is unbelievable. Having worked for years in traditional trim, it is so easy to dismiss critical devices as “dumb” sensors when our industry is just now being exposed to more state-of-the-art design.

Conclusion

Airbags are safety features that work in incredibly violent ways. Installed incorrectly, they can be more dangerous than the car accidents from which they are designed to protect us.

As trimmers, we often walk a fine line between what is safe and what is not when deciphering new technologies and learning how to incorporate them into our services. However, we have a duty to ensure that nothing we do to clients’ cars puts them or others unknowingly in danger.

When it comes to repairing seats with side impact airbags, some trimmers feel pressured by customers into sewing beyond their comfort zone and taking jobs or chances that they shouldn’t. These trimmers sometimes rely on casual online feedback because it sounds correct. Others simply speculate what “should work.”

At the end of the day, trimmers need to ask themselves if taking a job is worth the cost of someone’s life. And if it’s not, simply declining the work.

Some customers might not understand and become angry, but most will value an educated or concerned answer that explains to them what exactly is at risk — not just for them, but all passengers.

I’ve spoken with many customers who were not aware of the potential danger of having their seats retrimmed, as the trimmer made no mention of their abilities or concerns regarding airbags. Some jobs I’ve encountered were done with care and precision, while others were almost guaranteed to fail and cause injury because the trimmer did not want to turn away business.

Despite warnings, some trimmers are still going to repair seats with side impact airbags, risking their business’ livelihood and customers’ safety. There are always those who feel they know more than the rest or feel they have one or two good examples that justify their decisions.

To those trimmers, I ask that you at least make a concerted effort to examine the construction of the seams before you take anything apart. Measure the stitch count, examine the weight of the thread on both bobbin and top stitch, and note any small details in order to replicate the seam as close as possible. And by all means, please educate customers on the risks that they are requesting you to take.

Joseph Pavich is an interior design engineer for Tesla Motors. He’s also the former owner and operator of JPM Coachworks and has worked for Tier 1 suppliers such as Adient and Futuris. All information and opinions expressed in this article are Pavich’s alone and do not necessarily represent the viewpoints of Tesla Motors.

Great article and very insightful. I can think of instances when there is very little to no choice. Case in point: mustangs and mini coopers and some lexus’s where factory covers aren’t available, and the airbag seams split to a point that airbags are exposed. Is the client better off not having a seam at all ? If there isn’t a leather kit available and no factory parts available, what do we do?

And side note Joseph- Tesla model X 2nd row bucket seats- the airbags are attached using a special rivet, and since it’s one piece (backrest and cushion) how are we suppose to do a repair on the bottom if cover can’t be detached? I’d like your insights on that, since we work on plenty of Tesla’s in Las Vegas.

Great article and well written!

Thanks Ryan. Definitely a lot of tough decisions to make on repairing/replacing the seats. Knowing what I do, I would almost say it’s safer to eliminate the airbag with the customers consent if no factory or aftermarket kits are available.

As for the Model X. That program began before I started so I don’t have much knowledge as to what is going on with the rivet. I would imagine that it gets drilled and replaced with a like component but I’m just guessing. If I find anything, I’ll let you know but I might be prevented from sharing service data.

Knowing what you do as an interior design engineer, how can it be SAFER to eliminate the air bag.

I’ll preface this by saying it’s my opinion only, but I would imagine that having no airbag is safer than having one that does not work properly or malfunctions during deployment. I justify that opinion by thinking in one scenario, you know what you’re getting (no bag) and in the other, it’s a gamble. Certainly a risk either way. I’m sure a good argument can be made to the contrary as well. If I was selling something to the customer, I’d rather be sure as to what they were getting. Again, just opinion there.

Thank you for a very informative article.

However I must enfatilly disagree with eliminating an Air Bag. First I believe it would be against Federal Regulations. Second the Insurance Company that would be liable for claims would not pay for injuries as they have based premiums on an air bag equipped vehicle. Lastly the trim shop would have a very large liability maybe even criminal charges..

Hi recently deployed drivers side airbag on seat on a ford connect grand tourneo as you explained in great detail it has burst the stitching …is this something you would repair or would know of someone youd recommend to repair ?….or is it going to have to be a swap…many thanks for your time and article

David

Many

Excellent article and very well explained. This is the whole reason I will not sew any seat covers that have any kind of airbag in them. Some customers understand and others get upset, but to me it is not worth it to take any chances and I won’t.

As a Father, I don’t want someone’s child paying for the cost of their parents “needing” a custom seat cover if something should go wrong.

Why is the information from manufacturer’s not more readily available so that repairs can be made, and they can be done so that airbags deploy properly and effectively. Is there an industry standatd that manufacturer’s adhere too? If so where can that infirmation be found? As a trimmer with more, and more vehicles designed with airbags into thir seats and dashboards its hard to find the information to replicate the manufacturer’s design. I have searched alot and there is very little information abailable. As stated in the article there are tall tales about what will work and what will not, but in my opinion, like anything else in the automotive industry seat covers ect.. should be able to be replicated. So how, as a trimmer should i go about redesigning a customers interior that would like to set their vehicle apart from the masses f oh r a custom look?

I have done exactly the same Tom, more vehicles do now have them and there is so little information. I have just finished a retrim and the only way I could sort of replicate it was by pulling the seams apart on the old cover to see how much it took to rip apart and then try different threads on the new cover until I thought it was the same. It’s a crude method but what else can you do?

Unfortunately, the covers are not made to be repaired. That’s why there is no information out there. The amount of testing a factory seat goes through to make sure the airbag deploys as intended is crazy. They can deploy over 20 seats just to make sure a single material change doesn’t affect anything. As a repair shop, there’s really no cost effective way to test your repairs so you would be guessing at best.

Hate to say but i been resewing air bags seams for years for body sjops and retsil customers and i know most shops atound me also have. Should i have a customer sign a waver excluding my shop from any liabilities..

I’ve seen this before. Body shops trying to save money by doing quick repairs. Trust me on this one, they’re leading you down a road that could close your business. I’ve seen this happen before where an airbag repair takes place and it doesn’t deploy or deploys incorrectly. Then, their insurance goes after everything you have. I’ve seen small shops close up because of it.

Do you have any hard copy information or links to small shops being sued or closing up because a side impact airbag did’nt deploy properly after a repair? I have many hours of research on this subject, and I can’t seem to find any. Countless lawsuits on steering wheel air bag failure, but nothing on SIAB.

A number of years ago when I ran my own shop, I spoke with a few attorney’s and insurance providers about getting proper coverage for work performed. The provided me with a few examples of what we’re talking about. Both settled with insurance but it financially depressed them through lawyer fees as the process took so long. One even came out clear but the legal process took it’s toll. The injured party’s insurance first went after the business’ insurance coverage and then after the owner when the coverage wasn’t there. Even though he may have been removed from liability didn’t prevent them from spending the money and making him jump through hoops regardless.

Great Article

We just had an older leather seat split open.

The leather shrank and the seam opened.

The airbag didn’t deploy.

There’s no factory replacement available ,

There’s no leather kit.

What does the owner do ???

Tough situation. I would say the customer would have to make the choice of continuing to search for a replacement or request to have the airbag removed from the vehicle so that the seat can be repaired. No different than having them request an aftermarket seat to be installed at that point.

Side Impact Air Bags have been federaly MANDATORY in automobiles since 1998. If you remove the airbag, you will be breaking federal law. The odd thing is, there is NO law that says, you can not repair a seat cover with a SIAB. But if you do, and it has been proven in a court of law, that the air bag didn’t deploy properly, whether or not the deployment had anything to do with the repair or not, you can be sued for liable because you were the last one to touch the seat.

This is correct. Insurance companies will drag anybody that touched the car into the legal proceedings if needed. There’s grey area when it comes to installing aftermarket seats and customs for “off road use” etc, but i’m no lawyer and things vary state to state.

Wouldn’t you have the same liability if you sew it back or remove the airbag

Why isn’t Joseph Pavich responding to any of the comments. This is a very big deal in modern trim. If there is no industry standard and different manufacturers use different thread and material with different specs. Even if a shop purchased the special machine they still will not have the correct information information to use it. Let alone use it on any of the different seats that come thru the door. What about pillars and headliners? Even a basic wrap will not be the factory material will this effect the 7 hundredths of a second? (Note : that video is a joke with out any thing to validate the actual timing of events). What about seat repairs? Will doing a vynil or leather repair effect the outcome? What about seat foam modifications that are becoming common with the uncomfortable seats being produced? What aboit aging seats? If it is this sensitive of a system how can it age? Seat covers change composition with age that will change the effect of the airbag. Along with defective airbags. Airbags age as Well bit according to this article even if you replace the airbag with original location and hardware it may still not work properly. I feel at this point it is up to the manufacturers to create a common long term sustainable/ repairable solution for a problem they are creating and them telling people there is no way to fix it repair or maintain.

Sorry, I’ve been checking the facebook thread but forgot about these.

The point of the article is that the average shop is not equipped to repair, resew, or remake a seat cover that contains an airbag seam. The factory explodes many airbags just to test if a slight change in stitching or material will have an impact on deployment times. Unless you’re willing to invest in high speed cameras and blow 20 or so covers to validate that your technique works properly, there is no way to be sure you’re doing safe work.

In regards to the manufacturers providing a way to repair…unfortunately, they’re only required to produce replacement parts for 10 years after a model goes out of production. After that, there is not much you can do aside from removing the airbag system assuming the customer has agreed to it.

Sorry to say, but this “what can you do?” excuse is lame.

What you can do is turn away the job. Simple as that.

None of us are millionaires. We’re all struggling to work and keep the lights on. But when it comes to someone’s safety, you turn the job away.

Would you like someone taking risks with your life or your family’s life?

Man up.

Exactly! I wish more people would realize this. The alternative is to turn the job away. Nobody is twisting your hand to repair a safety device and you’re under no obligation to risk your businesses well-being or someone’s safety because a customer insisted. I feel most customers would be happy to know just how complicated these systems are and that it’s not worth shortcutting.

I am not an advocate for or against SIAB repair. My problem is with large corporations using nothing more than scare tactics to dissuade the repair industry to not resew this cover. I can’t believe that if you used the same thread and stitch length on that one seam, the air bag would not deploy properly. There really is not anything more to it than that. The seam is made to fail. Maybe not at the same millisecond, but that is just another scare tactic. Surely someone can duplicate that seam with an industrial sewing machine. Why can’t you admit this?

There actually is a lot to it and a millisecond is a lot when you’re involved in a side impact crash. I’ll give you real world example…a good while ago I was involved sewing plant transition. In order to certify the new plant, a group of seats had to be deployed to verify timing. Despite having the EXACT same materials and thread as the original sew plant, the seats were all failing the tests. Everyone was scratching their heads trying to figure out what was wrong. As it turned out, there was a seam that was not part of the actual airbag seam that needed to break as well in order to relieve tension in certain areas. It wasn’t obvious at first but once it was confirmed with the engineering drawings, they realized that’s what the problem was. That seam was sewn with the wrong stitch length and cause a significant delay in operation despite not being the visible “break away” seam.

That’s not scare tactics. When people’s lives are in danger, you don’t leave it up to “that’s good enough.” The point is not IF you can replicate the seat properly. The point is, can you do it and KNOW that it will work as intended. Without being to test your methods on multiple seats, you cannot say that you’re doing things right.

Who’s talking about “scare tactics”?

Automakers have invested millions of dollars into R&D to ensure their airbags deploy as designed. If it was as simple as using an ordinary sewing machine, don’t you think automakers would have done that instead of wasting so much money?

If you have the ability to match OEM air bag seams and can certify they work, then go for it. But most shops don’t have the insider knowledge or special equipment to do that.

Any of us can sew a stitch that fails when an airbag is discharged. That’s not the issue.

The issue is: Can you guarantee that your seam breaks at the millisecond it’s supposed to and directs the airbag in the direction it’s needed to go in order to save a life? I don’t know how to measure that. Do you?

If the answer is no, then stay far away from airbag seams.

The millisecond scenario is a scare tactic. Oh and by the way, I just replaced the two side inserts in an air bag backrest that someone already replaced before me. Did I get them off the hook and now it’s on me? Oh wow.

A couple questions for you Joseph. I’ve herd that airbags have a life expectancy of 10 years, do they expire kind of like a fire extinguisher? And why don’t the manufactures go back to the external airbags like in a mid 2000 Chevy? where it’s not hidden in the seat and covers have to be specially made and have all of the problems of seams popping, and specialized equipment to manufacture and go awry of the car right to repair law?

Knowingly remove an airbag???

According to NHTSA.gov . . . (link below also)-(bottom of page 20)

_______

Making safety devices and elements inoperative

(a) Definition.–In this section, “motor vehicle repair business” means a person holding itself out to the

public to repair for compensation a motor vehicle or motor vehicle equipment.

(b) Prohibition.–A manufacturer, distributor, dealer, or motor vehicle repair business may not knowingly

make inoperative any part of a device or element of design installed on or in a motor vehicle or motor vehicle equipment in compliance with an applicable motor vehicle safety standard prescribed under this chapter unless the manufacturer, distributor, dealer, or repair business reasonably believes the vehicle or equipment will not be used (except for testing or a similar purpose during maintenance or repair) when the device or element is inoperative.

_________

https://www.nhtsa.gov/sites/nhtsa.dot.gov/files/documents/motor_vehicle_safety_unrelated_uncodified_provisions_may2013.pdf

_________

You CAN NOT remove an airbag if you know that the vehicle is still going to be used. As of 8/31/1997, 100% of passenger car production must have air bags for both front outboard seating positions.

Not looking to start a debate here, at all! Just wanted to share a bit of research.

This is not accurate I have problems getting replacemt covers for newer vehicles let alone 10 years old. You still have not provided an actual means of fixing or replacing these parts. You did not even mention any thing about repairs ie vynil and leather non replacement, or the fact insurance company’s send these damaged seats to use to resew and or do panel repcaments. Also they do not habe any control how a seat will age or any actual means to test that theory. I just worked on a 2014 vw the vynil seat was so hard it literally cracked from taking the cover off. Regardless of I do the work or not that air bag will not deploy the same it did the day it was manufactured. That seat did not have an air bag chute and it had a traditional reinforced seam. The manufactures take so little care of the airbag issue I just read an article about air bag recalls pending https://www.google.com/amp/s/www.caranddriver.com/news/amp14499263/massive-takata-airbag-recall-everything-you-need-to-know-including-full-list-of-affected-vehicles/

. All I am asking for is a clear answer on how to handle these seats. Either the means to service them is made redally available to trim shops or manufactures have to be required to have replacement covers available.

Joseph Pavich, great write up. Any advice for a trimmer who is getting pressed to replace all the vegan in a Model S Performance with real hides and alecantera centers? The person pressing this trimmer is his wife. So much so she is threatening to get rid of car if she has to sit on vinyl seats this summer!

I got to this article late so forgive me. First having a waiver signed or even offered is a sign the shop is doing something wrong. Years ago a shop removed headrest from a customers vehicle and the shop had a signed waiver. The customer gets severely injured from the car rear ending them. His insurance company sued and the the insurance company of the car who hit them paid off close to a million dollars. Now that insurance company found the signed waiver and that was evidence that had the headrest not been removed the injuries would have been substantially less or maybe not at all. That shop didn’t have coverage for the near million nor was the owner incorporated so you can guess what happened from there. To this day he never recovered what he loss. Because I know him I will not disclose the shop or his name. There’s enough business we don’t need to extend our liabilities and risk it all. There’s not enough money in a repair to risk as well and finally most of us trimmers are not engineers although we may be as talented.

WHEN THE SEAM ON A SEAT SPLITS OPEN AFTER WARANTY EXPIRES, THE AIRBAG WILL DEPLOY SOONER THAN DESIGNED TIME, IS THE MANUFACTURER LIABLE.

HOW LONG BY LAW THAT AIR BAG IS SUPPOSED TO BE FUNCTIONAL?

THANK YOU FOR YOUR ANSWER

i’ll put in my 2 cents.. I install aftermarket covers all the time and body shops call me for airbag repairs almost weekly, I now use a national parts search to find a factory part when I can. if I cant find a factory part or an aftermarket part (only once this has happened) I wont touch an airbag seat, I saw a vehicle with my own eyes that had an airbag cover repaired and the airbag only partially split the seam , ballooned out near the bottom of the seat back. The body shop had me come look at it, you could see that the cover had been deployed and resewn, 2 sets of sewing holes and wrong thread.. As soon as you alter the OE design either by resewing or using and alternate material (vinyl) you have changed the mechanical characteristics of the airbag seam. you are now responsible. As pointed out deployment several hundredths of a second slower or even faster can change the effectiveness, its why manufactures test, not for scare tactics, its to get it right… in short. don’t touch them . signing a waiver also as indicated above shows you are doing something that is not factory and you are validating that you are aware of this, imagine a person dies because you altered the seat, “but I have the waiver!” yup you knowingly put the customer in harms way , the family would win in a court of law. they aren’t going to say.. “oh heck he has a waiver!” here is another area that gives me wonder.. seat covers that go over air bag seats.. they will inevitably slow down the deployment.. there is no way these comply with federal motor vehicle safety standards. now it has to blow through 2 seams . I personably think the right answer is stay away from resewing them. for seats where there is an aftermarket alternative.. use them, JMO

Makes me think twice about the seat covers (protectors) I have over the factory leather to protect it from my dirty working self. No way the airbag will deploy correctly but I never even gave it a second thought. Since seat airbags are mandated at this point, why are seat covers even allowed to be sold?

Here’s my question bc I have a differ dilemma. I own a 1994 4runner and I found some great looking 2011 Civic seats at the local pick n pull . Now me being a fabricator it’s easy to get the seat rails to work in my 4runner.

However both side bags had deployed. My question is is it easy to get the side stitch back up without replacing the air bags. Since my 4runner is old and has no need for them. I just want to know if it’s possible to fix the fabric that broke open.

I have a question concerning the removal of the seat cover itself. Is it ok to remove the cover or will that make the airbag deploy. In other words – is the cover independent from the airbag ?

Thank you

Stefan

Removing the cover will not cause the airbag to deploy. Disconnect the battery and wait 30 minutes before working on the seat just to be safe. Some covers are completely independent of the airbags while others have a sewn pouch that the airbag slips into. If that is the case you’ll need to unbolt the airbag to remove the cover.

Are the manufacturers of automobiles and their original parts to be held accountable,when such parts are compromised, mishandled,damaged,modified or altered over the course of their lifetime.Automotive Recyclers Association and some involved in their testing of airbags witnessed and videotaped failed deployment and schrapnel from airbags,long before many of us ever even heard of Takata. I know this because I predetermined one such airbag as repainted,and insufficient for resale and unfit for ARAs testing.A coworker of mine sourced this to ARAs testing.Many of us have seen the schrapnel and video of failure,yet no mention of how junkyards second hand airbags(always sourced from vehicles with totally unknown history) could have led to Takatas demise.One of the earliest claims of failure,Alabama about 2004, have led Takata to secretly test airbags after hours,SOURCED FROM JUNKYARDS!!! Talk about potentially taking the first step down the wrong path…assuming validity of such questionable safety components.Nobody is required to think as others say we must.Sorry ARA,I’ve seen your malicious influence peddling upon regulators,when you told them you can determine the INDETERMINABLE,that airbags can be determined as good.Simply appearing to not be blown is just not good enough.When testing airbags the CONFIRMATION as good,can not come until AFTER THEIR DEPLOYMENT.Prior to this exact moment of deployment,good is INDETERMINABLE .

Will my reassembled seats airbag deploy properly? Maybe…. Maybe not… Will a junkyards ‘recycled’ airbag function properly? Maybe…. Maybe not… These questions become an obvious BEATING OF A DEAD HORSE,when one realizes THE FOLLOWING TRUTHS, 1 Not a single ‘tested’ airbag means anything regarding the next. 2 UNCERTAINTY EXISTS with all airbags and reconstructed seats. 3 UNCERTAINTY REMAINS until such components exact moment of deployment,and close study how they performed…

I have a question. So my drivers power seat leather ripped. If i was to buy a seat from the recycler that is intact with the airbags not blown and install it instead of repairing the original seat would i have to re-program the computer? All input would be greatly appreciated. Thanks in advance.

Depends. Mercedes, recent Volvo and a few others, will require a “reset” confirming all is well.

Many OBDII readers will have the info to confirm if all is OK, but few can reset.

Typical re-set at a dealership is $150, takes all of 5 minutes With the proper diagnostic tool.

I bought an aftermarket comprehensive tool for Mercedes, Not cheap. it has paid for itself now, but took a while.

As to resewing an airbag seam, I did some development work a long time ago for a car company. The variations that were specified, told me right there, never resew an airbag seam. The thread, the strapping, All play an important role.

Consider it this way, how would you answer in a wrongful death lawsuit that you saw the do not resew tag and and did the work anyway? I hope you are incorporated or are a LLC on solid footing or bye bye all your assets, and your insurance carrier probably has a clause protecting them.

I had a long term customer that needed major seat work. I advised I could repair the seat bottom, but not the backrest. She came by later with the work done elsewhere, what do you think? It was a visually marginal job, I did not judge that, but hoped her heirs and executors would be happy.

It is a loss of revenue. I wont even install aftermarket upholstery that is “airbag” ready. it is not tested to the same standards as the OEM’s do. NO aftermarket provider is wasting a whole car with a crash test dummy. “we have 2 million in liability insurance” that is nice and small potatoes in California.

Ya, except that’s bullshit. I can think of one large aftermarket manufacturer that actually sews oem covers as well. I’m sure there are others. No, going to “honest Jose’s house of stitch and taco benderia” will probably not work out well, but you’re 100% fucking wrong on your assumption “no aftermarket does testing”. Stop posting wrong info and erroneous “opinions”, you window licking cumguzzler.

Neat, but I’ve seen the hack jobs put out by “jpmcoachworks”. To consider him an authority on anything is laughable, and one of the MANY reasons this websites a fucking joke.

When airbags first came out for front driver seats only, the manufacturers tested them thoroughly and said they only offered 5% survive-ability to a HEAD ON CRASH, and ONLY to a HEAD ON CRASH. and ONLY when you ALSO used your LAP and SHOULDER BAG. ONE such airbag added $200 to the cost of the car. Lap and shoulder belts were economical and effective. But you have to USE THEM. Now the insurance people could’ve ensured compliance (wearing of belts) by telling people their coverage would be reduced if they were

found at the scene of an accident to not be wearing belts. But instead, they, and a bunch of people who think it’s their business to impose their views on others, lobbied Congress for air bag mandates. So now today, we have 8 – 10 air bags in cars. The explosive absorbs moisture and becomes more powerful, blinding, maiming, or killing some accident victims. The bags have raised the cost of vehicles thousands of dollars. Add to this the cost of other unnecessary mandates like tire pressure monitoring systems, backup cameras, anti-lock brakes. All of which means poorer people can’t buy a new or used car as often, so they drive their old hulks with suspect brakes and other problems. Has this made us safer as a nation? Where does it end,, when we are bundled up into a cocoon before being transported?

By the way, notice that race car drivers don’t use air bags!

If anyone here has good counterpoints to my arguments, I’d like to hear them.