Want to learn how to bind an isolated hole in a vehicle carpet? Check out this step-by-step tutorial by Brent Parker of Brent Parker Motor Trimming in Glenorie, Australia.

“Sometimes it’s nice to not have to put a cut in from the edge of the carpet to bind the hole,” said Brent. “I’m sure a lot of you know how this technique is done, but for the guys who don’t, here’s how it’s done.”

1. Cut your carpet and binding material

Cut the hole you require in the vehicle carpet. Be careful that it’s the correct size and location. Otherwise, you could ruin the project.

Next, cut two square pieces of material about an inch bigger than the hole. I’m using some cheap vinyl to illustrate.

2. Trace the hole on your binding material

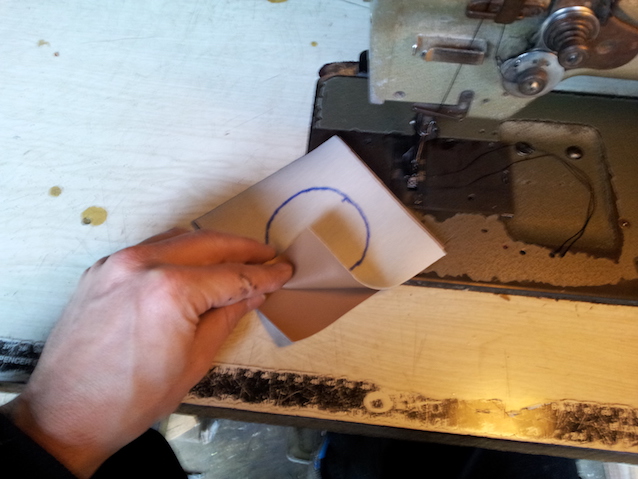

Put one piece of vinyl underneath the carpet face-down and trace the hole.

3. Sew the binding material

Place the two pieces of vinyl together with their faces touching, and the marked one on top.

Sew the two pieces together following the shape of the hole you traced. Be sure to use a small stitch length.

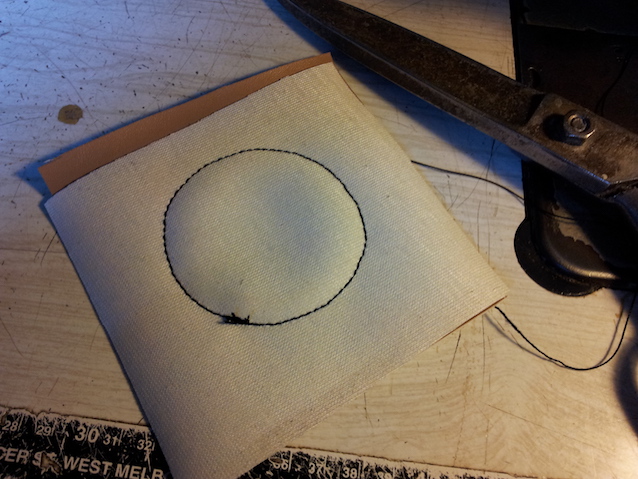

4. Cut out the hole

Cut out the inside of the circle, keeping close to the stitches.

5. Flip the binding material inside-out

After you cut the hole, turn the vinyl the way it’s meant to be — face out, with the seam on the inside of the circle.

6. Mark the circle

Using a vinyl pen or chinagraph, mark the circle where you will stitch the binding to the carpet.

7. Glue the binding material to the carpet

Glue one side of the vinyl binding material and the backside of the carpet together.

Make sure that the stitches are touching the carpet so that it’s even all around.

Turn over the carpet and pull the binding through the other side.

8. Sew the binding material to the carpet

You’re almost finished! Take the carpet to the sewing machine, make sure you give it tension, and start sewing on the line you marked slowly and carefully — tensioning as you sew because you want it even all around.

9. Trim the binding material

Lastly, trim the excess material off your binding, staying close to the stitches. Be careful to keep it even.

Here’s the finished product:

To see more of Brent Parker Motor Trimming’s work, follow them on Instagram and Facebook. Also, check out The Hog Ring’s “How To” section.

Only thing is a sharpie should never be used on vinyl

AMEN !!

Amazing!

what a great idea– thank you for sharing. – I’ve been looking for a way

It was simply a scrap piece to show how its done.

♥️✌️much thanks & appreciation for the tips n tricks!

Two points, no need to back stitch on the start as you’ll connect on the circle, and you don’t need to use a single foot.

This method works for leather as well but I should warn you to take care of unfinished edges on vinyl because over the years it can fray. One of the ways to protect the vinyl from fraying is to imagine at least a half inch larger than the finished edge and making relief “V” notch cuts all the way around the circle. Glue the entire back side of the top vinyl piece wait for the glue to dry then turn all your edges under, then sew it down about an eighth of an inch from the edges. Leather is different where all you have to do is burnish the edges to keep it clean looking.

Brent – “Thank you” for taking the time to share this. Always enjoy learning from the masters!

My father taught me years ago I have done lots of. Them I use leather instead of vinyl you don’t have to worry about edge fraying,

Waaaaaaaaaaaal thank you would love to learn more. Very straight forward tutorial keep it up

thank you! I struggle no more !!! LOL