There was a time when car interiors were made of various metal and plastic components that simply screwed or clipped together.

These parts were easy to disassemble for repair and then reassemble. Nowadays, interior plastics are fused together through a process called ultrasonic welding. You may be unfamiliar with the term, but I guarantee you’ve seen the results of this method before.

Watch this video to see how door panel components are ultrasonically welded together to better understand how it works:

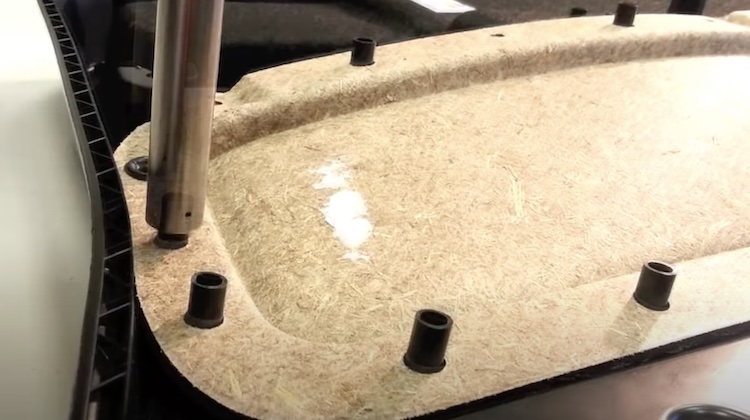

Modern vehicle interior components are designed to be assembled using a method called plastic staking. As you can see in the video, one part has several protruding plastic stakes on the underside and the piece to be joined with it has an equal amount of holes in which the rods are inserted. The parts to be joined are carefully aligned and a welding tool, typically consisting of a transducer, booster and welding horn, is applied.

The welding horn applies pressure and ultrasonic vibrations to the plastic components, causing localized heating. This heating softens the plastic, allowing it to meld together and form a robust bond. Once the joint cools and solidifies, the result is a fused connection that is both strong and precise.

The benefits to ultrasonic welding are numerous. It’s quick, easy, clean, generates a minimum amount of heat and doesn’t let off any toxic fumes.

The biggest drawback to ultrasonic welding and plastic staking is it’s irreversible. Unlike the good ol’ days where you could separate and fix joined panels, plastic staking throws a curveball, making routine repairs a head-scratcher.

For upholstery pros dealing with these parts, it’s become a bit of a puzzle. They’ve had to get crafty, coming up with clever ways to separate and reconnect plastic parts. Most shops are shaving off the melted portion of the stake and running a washer screw into the remainder of it. Others are using various epoxies and glues to reconnect their parts. Some are even turning away the work altogether.

It seems for now, plastic staking and ultrasonic welding are here to stay. Just like automakers come up with new methods for manufacturing car interiors, we have to come up with methods for repairing them.

In Europe and Asia, trim shops have found ways to reconnect separated components using ultrasonic welders. The Hog Ring is currently looking into this and will soon report on our findings. Meanwhile, here’s a little teaser video:

Recent Comments